What is the Filter Press - Computerized Filter Press Machine

페이지 정보

작성자 Sherlyn 작성일25-01-09 06:54 조회6회 댓글0건관련링크

본문

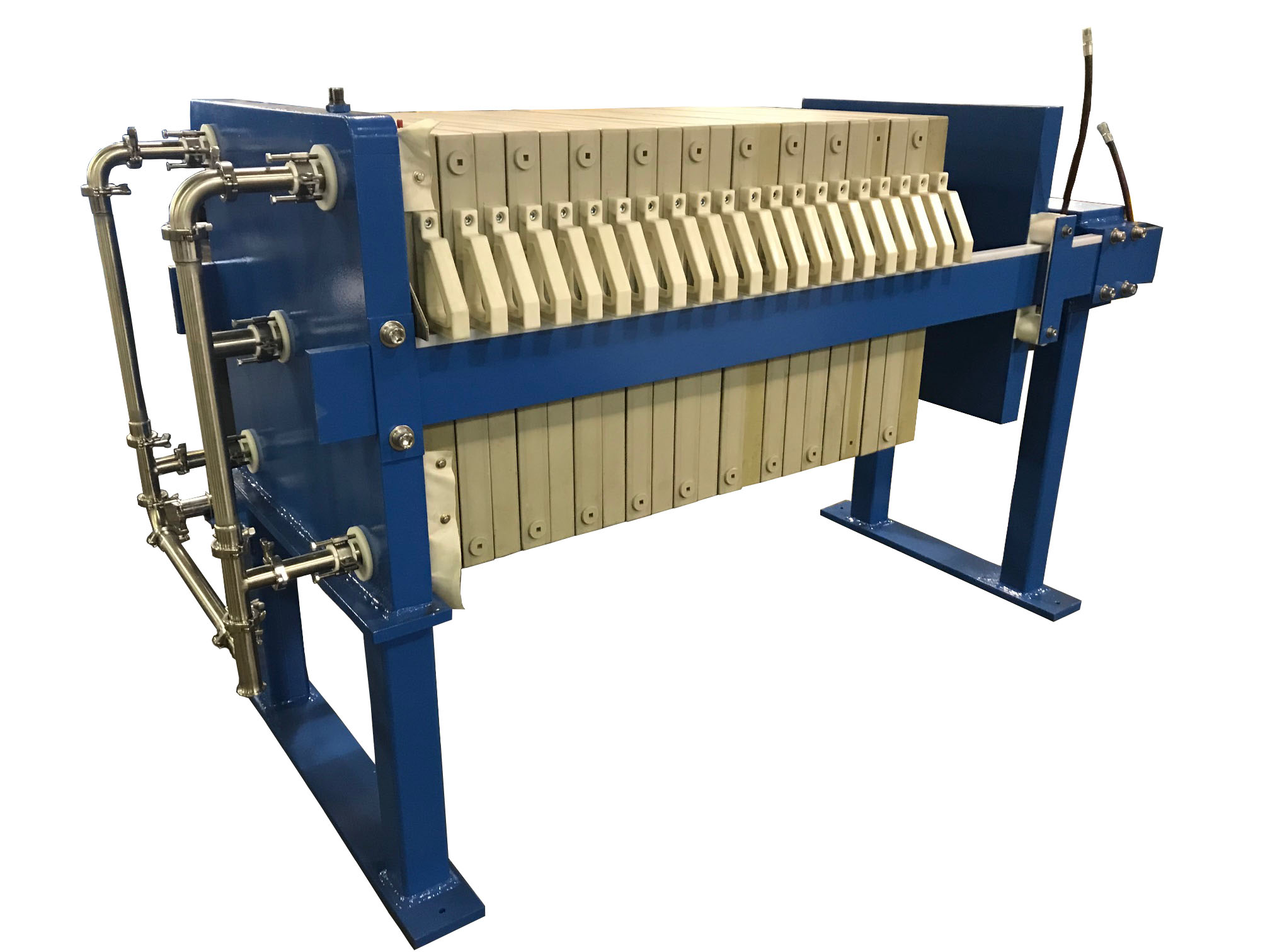

Overall dimensions of the machine (length x width x top) (mm): the general dimensions of the filter press. Basis dimensions (mm): the muse dimensions required for the installation of the filter press. Working strain of hydraulic filter supplier chamber (MPa): the maximum stress utilized in the course of the filtration course of. Motor power (KW): the ability of the motor used in the filter press. Complete weight of the machine (KG): the entire weight of the filter press. Third, to reduce operating costs by achieving drier cakes or using fewer chemicals, operations are looking at changing belt presses with newer fashion filter presses that may typically achieve a drier product while using fewer chemicals. Aggregate plant operators who may be acquainted with older filter presses often confer with the filter presses on the market in the present day as ? This text will clarify the distinction between older type plate and body presses and the newer model, increased pressure recessed plate and membrane plate filter presses used as we speak.

We promote used filter presses from a number of trusted processing equipment manufacturers, together with Hoesch, Shriver, and Netzsch, to call a number of. Federal Equipment Company additionally presents used filter presses of varied sizes, at the moment ranging from 15" to 64", so you will discover one to greatest match your manufacturing wants. By buying your used filter press from Federal Gear Company, you will be purchasing from a trusted title in processing tools.

Polypropylene filter plate for top temperature and strain resistance. Low moisture content of materials by filtering with high pressure. High restoration of solid matter with clear filtrate. Filter plate with gasket for top sealing efficiency during operation. The low weight makes dealing with simple and shortens filtration cycles. Easy structure with low failure price. When a filter cloth is broken or worn excessively, very dirty filtrate will exit the press, and Open Filtrate Discharge allows the operator to instantly determine the placement of the broken cloth. All Filter Presses are fed by some sort of slurry feed pump to drive the solids and liquid into the spaces between the filter plates. The stress created by the pumping action creates the force essential to separate the liquid and solids.

댓글목록

등록된 댓글이 없습니다.